Die cut sticker printing is a popular method used to create custom stickers in unique shapes and designs. Unlike traditional printing, die cut sticker printing involves using a specific cutting tool, known as a die, to cut out stickers into customized shapes.

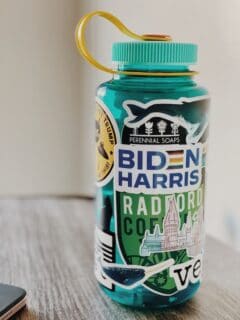

This technique allows for endless possibilities in creating eye-catching stickers that can be used for branding, marketing, and personal expression. Die cut stickers are known for their ability to stand out in a crowd and leave a lasting impression. Whether you are looking to promote your business, share your artwork, or simply add some flair to everyday items, die cut sticker printing offers a versatile and visually stunning solution.

Benefits of Die Cut Sticker Printing

- Customizable shapes: Die cut sticker printing allows for the creation of stickers in any desired shape or design, making them unique and eye-catching.

- Versatility: Die cut stickers can be used for a variety of purposes, including branding, marketing, personal expression, and product labeling.

- Increased visibility: The unique shapes and designs of die cut stickers make them stand out in a crowd, increasing visibility and drawing attention to your message or brand.

- Durability: Die cut stickers are made from high-quality materials that are resistant to water, sunlight, and general wear and tear, ensuring their longevity.

- Easy to apply: Die cut stickers can be easily applied to any smooth surface, making them convenient and user-friendly.

- Affordable: Die cut sticker printing is a cost-effective way to produce custom stickers in small or large quantities.

- Promotional tool: Die cut stickers are an effective promotional tool that can be handed out, displayed, or placed on various items to increase brand recognition and reach a wider audience.

What Material is Best for Die Cut Sticker Printing?

When it comes to die cut sticker printing, the material used plays a crucial role in the final quality and durability of the stickers. One of the best materials for die cut sticker printing is vinyl. Vinyl stickers offer numerous advantages such as durability, weather resistance, and versatility. Vinyl stickers are known for their ability to withstand exposure to water, sunlight, and general wear and tear, making them ideal for both indoor and outdoor applications.

Also, vinyl stickers are flexible and can be easily applied to various surfaces, including glass, metal, plastic, and paper. Moreover, vinyl is a reliable material that retains vibrant colors and crisp details, ensuring that your die cut stickers look visually appealing and professional.

How Die Cut Stickers are Printed?

They are printed using a combination of printing and cutting techniques. The process typically begins with the design being digitally created or uploaded. Once the design is ready, it is printed onto a sheet of adhesive material, which is usually vinyl. The printing technique used can vary, but common methods include digital printing or screen printing, both of which can deliver high-quality results.

They are printed using a combination of printing and cutting techniques. The process typically begins with the design being digitally created or uploaded. Once the design is ready, it is printed onto a sheet of adhesive material, which is usually vinyl. The printing technique used can vary, but common methods include digital printing or screen printing, both of which can deliver high-quality results.

After the design is printed, the sheet of adhesive material is passed through a die cutting machine. The machine uses a specially designed die to cut out the stickers into the desired shape or design. This cutting process is precise and allows for intricate details and custom shapes to be achieved. Once the stickers are cut, they are usually separated and packaged for distribution. Die cut sticker printing combines the precision of printing with the versatility of custom cutting, resulting in high-quality, unique stickers that are ready to be used for various purposes.

Common Lamination Types

To add colors, durability, and a glossy finish to die cut stickers, lamination is often used. Lamination is the process of applying a protective layer of material to the surface of the sticker, which can be done either during or after printing.

There are several common types of lamination used in die cut sticker printing, including gloss, matte, and high-gloss.

Gloss lamination provides a shiny, reflective finish that enhances colors and makes images pop. It also adds a layer of protection against scratches, fading, and moisture.

Matte lamination, on the other hand, offers a smooth, non-reflective finish that provides a more subdued, natural appearance. It also helps to reduce glare and fingerprints, while offering protection against wear and tear.

High-gloss lamination is similar to gloss lamination, but it provides an even brighter, more vivid finish. It also offers stronger protection against UV rays, moisture, and abrasions.

Overall, the choice of lamination type will depend on the specific needs of the project and personal preferences. However, regardless of which type of lamination is chosen, it can help to preserve the quality and life of die cut stickers, making them look great for a long time.

Die Cut Sticker Printing Guidelines

- Begin with a high-resolution design or artwork for optimal print quality.

- Ensure that the design includes a clear and visible cut line for accurate die-cutting.

- Choose a suitable printing method, such as digital or screen printing, based on your desired quality and quantity.

- Select a durable and versatile material, like vinyl, for the die-cut stickers.

- Consider adding lamination for added protection and a glossy or matte finish.

- Provide accurate specifications, including size, shape, and quantity, to the printing service.

- Pay attention to bleed and safety margins to avoid any design or cutting errors.

- Proofread and double-check the design for accuracy, ensuring that all text, images, and colors are as intended.

- Follow any specific file format and resolution requirements provided by the printing service.

- Specify any additional customization options, such as special finishes or treatments, if desired.

- Communicate deadlines and shipping preferences clearly to the printing service.

Can the ink bleed off the edge of the die cut sticker, or does there have to be a white edge all the way around?

Ink bleed off the edge of a die cut sticker can be achieved through a technique known as “full bleed” printing, which involves printing beyond the final trim line of the sticker. However, this technique requires accurate cutting and registration to ensure that the ink perfectly lines up with the edge of the sticker, without any white space visible. This can be difficult to achieve and requires appropriate printing equipment and expertise.

Alternatively, a white edge all the way around the sticker can be included as part of the design, eliminating the need for full bleed printing. The choice between full bleed and a white edge will depend on the design and desired effect, but it’s essential to consider cost, equipment, and printing limitations to ensure optimal results.

What File Types Can You Upload for Die Cut Sticker Printing?

When it comes to uploading files for printing, there are several commonly accepted file types that printing services typically support. These include vector-based file formats such as EPS (Encapsulated PostScript), AI (Adobe Illustrator), and PDF (Portable Document Format). These formats are highly preferred as they allow for scalability without loss of quality, making them ideal for printing purposes.

Moreover, high-resolution raster image formats like PNG (Portable Network Graphics) and TIFF (Tagged Image File Format) can also be used if the resolution is set to 300 dpi or higher to ensure a crisp and detailed print. It is always recommended to check with the printing service for their specific file type requirements and any additional guidelines to ensure compatibility and a successful printing outcome.

What’s the Largest Size You Can Print for Die Cut Stickers?

The largest size can vary depending on the printing equipment and capabilities of the service provider. Typically, printing services can accommodate sizes up to 52 inches in width and practically unlimited lengths. However, it’s important to note that larger sizes may come with certain limitations or requirements, such as the need for special handling or installation.

The largest size can vary depending on the printing equipment and capabilities of the service provider. Typically, printing services can accommodate sizes up to 52 inches in width and practically unlimited lengths. However, it’s important to note that larger sizes may come with certain limitations or requirements, such as the need for special handling or installation.

Do note that larger sizes may also require a higher resolution or DPI (dots per inch) to maintain the desired image quality. It is always recommended to check with the printing service for their specific maximum size limitations and any additional guidelines to ensure the desired size can be accommodated.

What’s the Standard Printing Time for Die Cut Stickers?

The standard printing time can vary depending on several factors, including the complexity of the design, the quantity being printed, and the workload of the printing service. Generally, the printing process for die cut stickers can take anywhere from a few days to a week or more. This time frame typically includes production time, which involves printing, cutting, and any additional finishing processes like lamination or special treatments.

It’s important to consider that rush or expedited services may be available at an additional cost if a faster turnaround time is required. To get an accurate estimate of the printing time for die cut stickers, it’s recommended to consult with the specific printing service as they can provide more detailed information based on their current workload and capabilities.

What’s the Minimum Required Quantity to Order Die Cut Stickers?

When it comes to ordering die cut stickers, the minimum required quantity can vary depending on the printing service provider. Typically, the minimum order quantity can range from 50 to 100 stickers, with some services requiring a minimum of 250 stickers or more. However, it’s important to note that ordering in higher quantities can often result in lower pricing as per unit cost of each sticker decreases with large orders.

Printing services may also offer package deals for bulk orders, making it more cost-effective for customers to order larger quantities at once. It’s important to consider the specific requirements and options of different printing services before placing an order to ensure that the desired quantity can be met while staying within budget.

Difference Between Kiss Cut and Die Cut Sticker Printing

The main difference between kiss cut and die cut sticker printing lies in the cutting process and its effect on the sticker backing. Kiss cut stickers are created by cutting the sticker material without piercing or cutting through the backing sheet. This means that the stickers remain attached to the backing, making them easier to peel off individually.

The main difference between kiss cut and die cut sticker printing lies in the cutting process and its effect on the sticker backing. Kiss cut stickers are created by cutting the sticker material without piercing or cutting through the backing sheet. This means that the stickers remain attached to the backing, making them easier to peel off individually.

Die cut stickers, on the other hand, are cut all the way through the sticker material and the backing sheet, resulting in individual stickers that are completely separate from one another. They can have custom shapes and do not have excess material around the design.

While both options allow for custom shapes, kiss cut stickers offer the advantage of being more efficient and convenient for individual distribution, while die cut stickers provide a cleaner and more polished look, particularly when used for complex or intricate designs. It’s important to consider the specific requirements of your project and the desired outcome when choosing between kiss cut or die cut sticker printing.

Conclusion

Die cut sticker printing offers a versatile and customizable solution for creating unique and eye-catching stickers. They allow for intricate and complex shapes, making them ideal for logos, branding, and creative artwork. Whether for personal use, promotional purposes, or branding, die cut sticker printing provides endless possibilities to make a lasting impression.

Popular Posts: