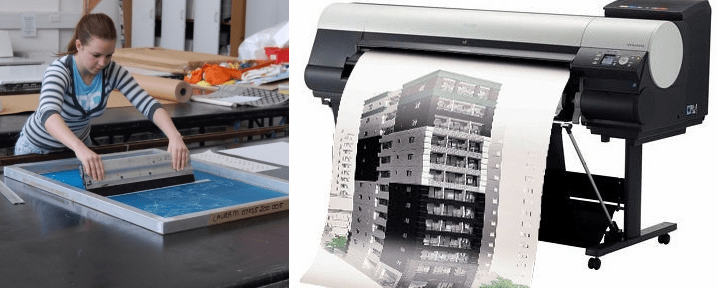

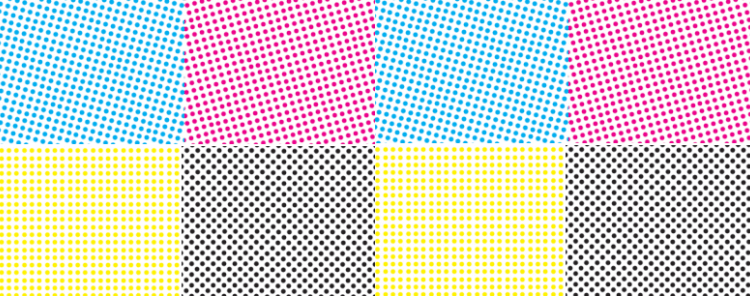

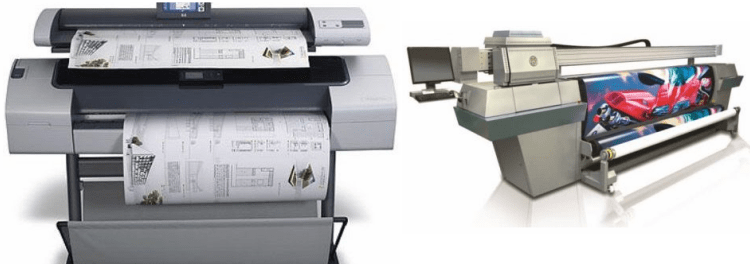

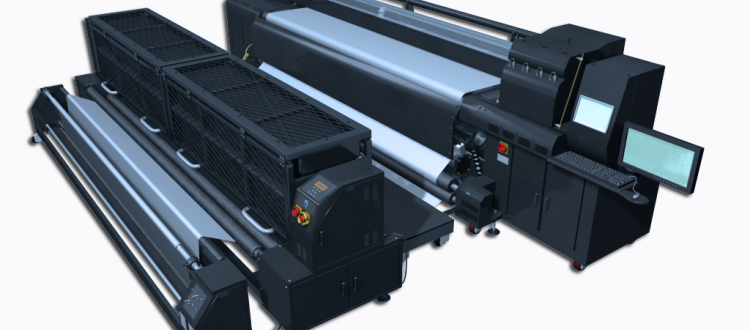

Screen printing and/or digital printing of PVC or Vinyl Banners. Also, no painting is allowed on vinyl substrates.

Can You Use Paint on Vinyl Banners?

I have received several questions regarding vinyl (flexible PVC) banners that I am going to answer over the next few articles. The first is, “What type of paint does one use on vinyl banners?”

The answer is that we don’t use “paint” per se on vinyl banners, although there may be some craft type stores that sell such a product. Coming from the commercial side of vinyl banners, though,