Learn what happens in dye sublimation printing on polyester fabric. Also, see how the process differs from heat transfer printing.

Question: Can you please describe how dye sublimation printing works? What kind of printer is used? Is it the same as heat transfer printing?

Wow! All very good and related questions to the dye sub and heat transfer printing of fabric, one of my favorite ways to print fabric and other items, although this answer will deal mostly with polyester fabric.

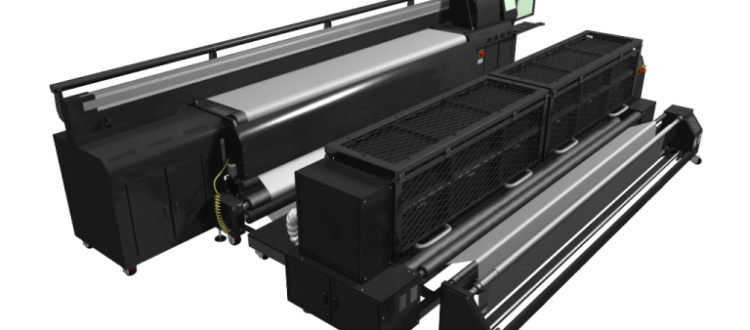

First, there are two types of sublimation printers. One uses ribbon so transfer color to a transfer paper, and the other is the same basic printing method as digital printing except there are differences between ink and dye. And the same printers can be used, although not interchangeably due to the differences between dyes and ink.

Digital Inkjet Printing

Inkjet printing uses, typically, what is known as the “four color process” printing method. The four colors are also known in shorthand as CMYK ink colors. CMYK stands for Cyan-Magenta, Yellow, and Black, which in any combination will print almost any color, not including neon colors or metallic colors, but most colors in the photo spectrum.

Because of the limitations of CMYK inks, additional colors have been added to some printers which are now known as 6 color digital printers, having added a light cyan and a light magenta to reach some of the harder colors to create in the printing process. Some printers have even added orange and green cartridges as well.

Dye Sublimation Printing

The Dyes

Dye sublimation printing is slightly different. The dyes used are similar to ink, but with some differences. The ink set for dye sub printing is also a four color process (also known in shorthand as 4CP), but the shorthand version here is CMYO, or cyan-magenta-yellow-overprint clear. Where is the black, you may wonder? It would be hard to create a full color spectrum without black!

To explain where the black went, or rather more accurately, where it comes from in CMYO dye sublimation printing, I need to delve into the rest of how it works.

Heat Transfer Paper

As stated previously, a standard 4CP inkjet printer is needed to print dyes as well, but the dye must be printed on a treated paper cleverly named “transfer paper.”

An image is printed in reverse (or mirror printed) on the transfer paper. The paper is matched up to a piece of fabric. The fabric cannot be a natural fiber because of the process that will be explained momentarily. The fabric typically used most of the time is polyester because it is a versatile fiber that can be made to look like anything from an oil canvas to a sheer fabric to a double-sided knit material that can be made into a double-sided flag or banner.

Pressing from Transfer Paper to the Polyester Fabric

Once the paper is matched to the fabric, it is run through heated rollers at high pressure. The rollers are heated to just under 400 degrees Fahrenheit or 210 degrees Celsius. As the fabric goes through the heated rollers, two things happen.

First, the pores or cells of the poly-fabric open up, while simultaneously the dye on the paper is converted to a gaseous state. The gas impregnates the open cells which close as they leave the heated rollers. This creates a continuous tone print which cannot be achieved using an inkjet printer because of the dot pattern laid down by the inkjets.

Other Materials that can be Dye Sublimated

If an item such as plastic or aluminum is coated with a special polymeric coating, these items can also be printed. Besides banners and posters and flags, other items that are commonly printed with dye sublimation heat transfer printing are clothing items such as T-shirts, table covers, sportswear, ID cards, and signs.

Advantages of Dye Sublimation Printing

Some advantages to dye sublimation printing is that the image is a part of the fabric, so it doesn’t peel off like ink on the surface of fabric or other materials and will not fade for many years. The dye cannot build up on fabric like t-shirts either. Everyone had worn a printed shirt where the ink felt like it was very stiff on the surface of the material, and over time it will begin to flake off. This will not happen with dye sublimation.

Other advantages are that the colors can be more brilliant than other types of printing because of the process of dye sublimation and the continuous tones that are achieved when the dye converts to a gaseous state. Because in printing garments the fabric is printed before the shirt or jacket is constructed, the image can go to the edge of the fabric which is not achievable typically with screen printed shirts.

More about dye sublimation printing on polyester cloth at www.visigraph.com/fabric-vinyl-cloth-banners/dye-sublimation-polyester-fabric-cloth-flags-banners

Popular Posts: