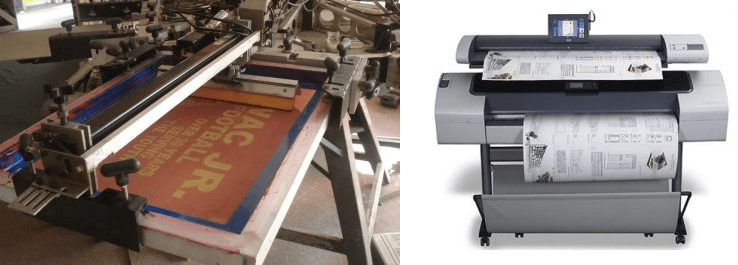

On-screen printing versus Dye Sublimation printing. Also, discover how pigment inks are different from dye sublimated inks.

Question: If cost is not a concern, what is better? Screen printing or dye sublimation printing?

While you could, in theory, print a fabric banner using screen printing equipment (t-shirts are most often screen printed and they’re made of cloth), the wider variety of things you can screen print cannot be printed using the dye sublimation printing process.

Dye Sublimation Printing

Here’s a short explanation to back up what I’m saying.

Fabrics Used

Dye sublimation banner or display printing is almost exclusively done on polyester fabrics, whether it’s an oxford, a knit, a poplin, a sheer, or a satin, to name a few styles of fabric.

The Ink Set

The dye sub print process utilizes a 4-color printing process similar to an inkjet printer, except instead of using a CMYK (cyan magenta yellow black) color build, it uses CMYO, exactly the same except for the overprint clear.

The dye sub print process utilizes a 4-color printing process similar to an inkjet printer, except instead of using a CMYK (cyan magenta yellow black) color build, it uses CMYO, exactly the same except for the overprint clear.

The Process

An image or photograph is sent to the printer, and it prints the image, in reverse, onto a sheet of transfer media, a treated paper. It is then “married” to the chosen fabric, and sent through another unit with heated pressure rollers. These rollers heat up to around 400F, and with the heat and the pressure, the dye changes from a solid to a gas, and fuses itself to the polyester fabric, creating a continuous tone print much like a photograph.

In my opinion, the dye sublimation printing on fabric is the most attractive of all printing available currently, but as as I stated initially, you can’t print dye sublimation on many items, at least not cost effectively.

Screen Printing

Screen printing can also be done as a 4CP print, but it uses a series of dots to create the CMYK print. Unless the printing is done with a very high LPI (lines per inch), it will appear to be much coarser than dye sub printing.

High Volume Printing

Screen printing is more often used for high volume, simple graphic runs. It is cost effective when run this way, but since cost is of no concern, if you can utilize a fabric banner material for your display, dye sublimation prints will always look much richer than screen printed prints.

Question: What’s the difference between pigment ink and dye sublimation ink?

Pigmented Inks

Pigmented inks have been used for digital printing of vinyl and decals and similar substrates due to their colorfastness. They are more expensive than dyes, and have less of a color spectrum than dyes do.

Pigmented inks have been used for digital printing of vinyl and decals and similar substrates due to their colorfastness. They are more expensive than dyes, and have less of a color spectrum than dyes do.

Dye Inks

Pigmented inks are typically weaker, as stated above, but dye inks will tend to run. However, over the past couple of decades, with the advances in digital printing technology, chemists improved dye inks by adding “hot” solvents which evaporate more rapidly, allowing dye to become the base of digital printing inks rather than pigment inks.

Most digital printers also use a heated platen, before, during, and/or after the printing process, as well as fans to aid quick drying and evaporation of the dye inks. Specially treated materials are also used that are “charged” opposite the dye inks which helps them cure more quickly.

Popular Posts: