Industrial labels can be an essential component of any manufacturing or industrial operation. These labels are designed to withstand harsh environments and provide critical information to workers, maintenance personnel, and customers.

Whether it’s identifying hazardous materials, tracking inventory, or providing operating instructions, industrial labels play a crucial role in ensuring safety, efficiency, and compliance. With an array of materials, adhesives, and printing technologies available, industrial labels can be custom-tailored to meet the unique needs of any application. In this fast-paced and ever-changing industry, having the right industrial labeling solution is essential to staying informed and ensuring success.

What are Industrial Labels?

Industrial labels are highly durable and specialized labels designed to withstand harsh environmental conditions and provide critical information to workers, maintenance personnel, and customers in industrial settings.

Industrial labels are highly durable and specialized labels designed to withstand harsh environmental conditions and provide critical information to workers, maintenance personnel, and customers in industrial settings.

These labels are made from PVC (vinyl) that can resist extreme temperatures, chemicals, abrasion, and UV exposure, ensuring that they remain legible and functional in even the harshest conditions. They can be made from a variety of materials, including polyester, vinyl, and polyimide, and can be screen-printed, or printed using thermal transfer, laser, or inkjet technologies.

Features of Custom Industrial Labels

- Highly durable and can withstand harsh environmental conditions

- Resistant to extreme temperatures, chemicals, abrasion, and UV exposure

- Provide critical information to workers, maintenance personnel, and customers

- Used to identify hazardous materials, track inventory, provide operating instructions, and ensure compliance with safety regulations

- Can be made from materials such as polyester, vinyl, and polyimide

- Can be printed using screen-printing, thermal transfer, laser, or inkjet technologies

- Customizable to meet the unique needs of any application

- May include barcodes or QR codes for easy tracking and inventory management

- Can be applied to a variety of clean surfaces, including metal, plastic, and glass

- Available in a wide range of custom sizes, shapes, and colors to suit different needs and preferences.

Industrial Label Material

Industrial labels are made of durable materials that are designed to withstand harsh environments and tough conditions. These materials vary depending on the specific application, but common materials include vinyl, polyester, polypropylene, and aluminum.

Vinyl is popular for its flexibility, resistance to moisture and chemicals, and durability. Polyester is known for its high temperature resistance and strength, making it ideal for use in industrial settings. Polypropylene is a cost-effective option that is resistant to tearing and abrasion. Aluminum is used for its durability, markability, and ability to withstand extreme temperatures.

Industrial Labels Finish Options

- Over-Lamination: a clear protective layer is applied over the label to increase its durability and resistance to abrasion, chemicals, and UV exposure.

- Die-cutting: the label is cut into a specific shape using a die to create a custom shape that fits the product’s profile or design.

- Embossing: the label is stamped with a raised design or text to give it a tactile feel and enhance its appearance.

- Foil stamping: a metallic foil is applied to the label to create a shiny, reflective finish that is eye-catching and adds a premium look to the product.

- Varnishing: a clear coating is applied to the label to give it a glossy or matte finish and protect it from moisture, chemicals, and UV exposure.

- Perforation: the label is punctured with small holes or slits to allow for easy tearing or separation, making it ideal for use as a product seal or tag.

- Adhesive options: different types of adhesives can be used, such as permanent high-tack adhesives, depending on the application and the surface where the label will be applied.

How Thick are the Industrial Sticker Labels?

The thickness of industrial sticker labels can vary depending on the material used and the specific application. Generally, industrial labels are similar to consumer-grade labels, with the main differences being in the adhesive or overlamination used to ensure their durability and resistance to harsh environments.

For example, vinyl labels can be as thin as 2 mils (0.002 inches) or as thick as 15 mils (0.015 inches), while polyester labels can range from 2 mils (0.002 inches) to 10 mils (0.01 inches) in thickness. Aluminum labels tend to be thicker than other materials, typically ranging from 0.003 inches to 0.020 inches in thickness. The thickness of the label may also depend on the desired level of adhesion to the surface where it will be applied.

What are the Shapes Available for Industrial Strength Labels?

Industrial strength labels come in a variety of shapes to fit different products, equipment, and environments. Some common shapes include rectangular, square, circular, and oval. These shapes are easy to produce and are commonly used for labeling products, machinery, and safety signage.

However, with modern printing technologies, it’s possible to create custom shapes that fit the unique requirements of a specific product or application. For example, labels can be shaped to fit around curves or corners, or to match the contours of a product’s surface. Custom shapes can also be used to create eye-catching designs that enhance the appearance of the product or equipment.

Types of Custom Industrial Labels

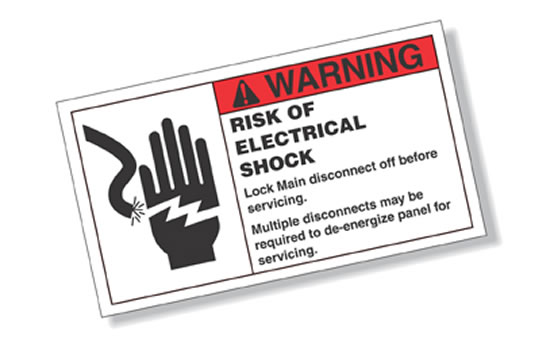

- Warning labels: used to alert workers and customers to potential hazards or dangers associated with a product or equipment.

- Safety labels: used to provide information about safe operating procedures, emergency shutdown procedures, and other safety-related information.

- Instructional labels: used to provide step-by-step instructions on how to operate or maintain a product or equipment.

- Asset labels: used to identify and track assets, such as machinery, tools, and vehicles, for inventory and maintenance purposes.

- Barcode labels: used to store and retrieve information about a product or equipment using a barcode scanner.

- Serial number labels: used to identify and track individual products or equipment using a unique serial number.

- Tamper-evident labels: used to indicate if a product has been opened or tampered with, providing an added layer of security and protection.

- UL labels: used to indicate that a product or equipment has been tested and certified by Underwriters Laboratories for safety and performance.

- Calibration labels: used to indicate when a piece of equipment was last calibrated and when it is due for its next calibration.

- Pipe markers: used to identify pipes and their contents, such as water, gas, or chemicals, to ensure that workers can safely handle and maintain them.

- Floor labels: used to mark walkways, aisles, and specific areas in a facility for safety and organization purposes.

- Reflective labels: used to enhance visibility in low light conditions, such as on vehicles or in outdoor environments.

What to Look for In Industrial Labels

- Material: Different materials have different characteristics, such as durability, resistance to chemicals, and adhesion. Choose a material that is appropriate for the environment and application.

- Adhesive: The adhesive used on the label should be appropriate for the surface it will be applied to and the conditions it will be subjected to.

- Print quality: The print quality should be high enough to ensure that the label is legible and the information is clear and easy to read.

- Size and shape: The label should be the appropriate size and shape for the product or equipment it will be applied to, and should fit comfortably in the available space.

- Color: The color of the label should be chosen to ensure that it is easily visible in the environment in which it will be used.

- Compliance: If the label is intended for use in a regulated industry, such as food or pharmaceuticals, it should comply with applicable regulations and standards.

- Durability: The label should be durable enough to withstand the conditions it will be subjected to, such as exposure to heat, cold, moisture, or chemicals.

- Information: The label should contain all of the necessary information, such as product name, serial number, safety information, and any applicable warnings or instructions.

- Barcode: If the label includes a barcode, it should be scannable and provide accurate and complete information.

- Tamper-evidence: If the label is intended to be tamper-evident, it should be designed to clearly indicate if it has been removed or tampered with.

Popular Uses of Industrial Safety Labels

- To identify and track assets, such as machinery, tools, and vehicles, for inventory and maintenance purposes.

- To provide safety information, including warnings, instructions, and emergency shutdown procedures.

- To mark walkways, aisles, and specific areas in a facility for safety and organization purposes.

- To identify pipes and their contents, such as water, gas, or chemicals, to ensure that workers can safely handle and maintain them.

- To store and retrieve information about a product or equipment using a barcode scanner.

- To indicate when a piece of equipment was last calibrated and when it is due for its next calibration.

- To enhance visibility in low light conditions, such as on vehicles or in outdoor environments.

- To indicate that a product or equipment has been tested and certified for safety and performance.

- To provide step-by-step instructions on how to operate or maintain a product or equipment.

- To indicate if a product has been opened or tampered with, providing an added layer of security and protection.

Surface Types and Adhesives Choices for Industrial Labels

Choosing the right adhesive for an industrial label is crucial as it ensures that the label stays in place and remains legible over time. Adhesive choices depend on the surface type of the equipment or product the label will be applied to. Some common surface types include corrugated metal, powder-coated metal, plastic, and glass.

Choosing the right adhesive for an industrial label is crucial as it ensures that the label stays in place and remains legible over time. Adhesive choices depend on the surface type of the equipment or product the label will be applied to. Some common surface types include corrugated metal, powder-coated metal, plastic, and glass.

Also, adhesives must be chosen based on the environmental conditions the label will be exposed to, such as extreme temperatures, moisture, or chemicals. Some common adhesive choices include permanent adhesive, removable adhesive, and high-tack adhesive. Permanent adhesives are ideal for surfaces that will not be removed or replaced, while removable adhesives are ideal for surfaces that will be replaced or removed frequently. High-tack adhesives are ideal for surfaces that require a strong bond, such as metal or textured surfaces.

Can Industrial Sticker Labels Withstand Harsh Environments?

Yes, industrial sticker labels are designed to withstand harsh environments. They are made of durable materials that can resist exposure to extreme temperatures, moisture, chemicals, and UV light. Industrial sticker labels are commonly used in industries such as automotive, aerospace, and construction where they are exposed to harsh environmental conditions. Additionally, industrial sticker labels are made with high-quality adhesives that ensure they remain in place even in the face of harsh environmental conditions.

Are Industrial Label Stickers Waterproof?

Yes, industrial label stickers are waterproof. They are designed to be water-resistant and oil-resistant, making them ideal for use in outdoor environments or areas where they may come into contact with chemicals or other substances. Industrial label stickers are made of water-resistant materials that prevent the ink from smudging or running, ensuring that the label remains legible even in wet conditions.

Yes, industrial label stickers are waterproof. They are designed to be water-resistant and oil-resistant, making them ideal for use in outdoor environments or areas where they may come into contact with chemicals or other substances. Industrial label stickers are made of water-resistant materials that prevent the ink from smudging or running, ensuring that the label remains legible even in wet conditions.

Also, they are commonly used in industries such as maritime shipping, where they are exposed to saltwater and other harsh conditions. These labels are made with high-quality adhesives that ensure they remain in place even in the face of water exposure. This means that critical information such as safety warnings, instructions, and identification codes can be reliably communicated, even in wet or humid environments.

Conclusion

Industrial labels are a crucial component in a wide range of industries. They are designed to communicate critical information such as safety warnings, instructions, and identification codes, ensuring that equipment and products can be identified, tracked, and maintained effectively.

Popular Posts: