Industrial laminated stickers are a versatile and durable labeling solution commonly used in various industries. These stickers are designed to withstand harsh environments, ensuring long-lasting and readable labels. The lamination process adds an extra layer of protection, making them resistant to chemicals, abrasion, moisture, and UV rays.

With their vibrant colors and clear visibility, industrial laminated stickers are ideal for applications in manufacturing, logistics, construction, and other demanding environments where durability and clarity are essential. From warning signs and safety instructions to product identification and branding, these stickers provide a reliable and cost-effective solution for all labeling needs.

What is an Industrial Laminated Label?

An industrial laminated label is a type of label specifically designed for use in industrial environments. It is made by applying a layer of lamination over the label substrate, creating a protective barrier. This lamination process enhances the label’s durability and resistance to various elements such as moisture, UV light, chemicals, and physical wear and tear.

Industrial laminated labels are commonly used for labeling equipment, products, and machinery in manufacturing, construction, logistics, and other industries where labels need to withstand harsh conditions. These labels are highly visible, with vibrant colors and clear printing, ensuring the information remains readable and intact for an extended period.

What Material are Industrial Laminated Stickers Made of?

Industrial laminated stickers are typically made of a combination of materials to ensure durability and protection. The base material of these stickers is typically vinyl or polyester, known for their strength and resistance to tearing. These materials are able to withstand various environmental factors, including moisture, chemicals, abrasion, and UV rays.

To add an extra layer of protection, a laminate is applied, a thin layer of clear film made of polyester, vinyl or polypropylene. This lamination film acts as a shield, providing resistance against moisture, chemicals, and physical damage. The combination of robust base material and lamination film ensures that industrial laminated stickers are able to withstand harsh conditions and maintain their quality and appearance for an extended period of time.

Common Uses of Industrial Laminated Stickers

- Equipment and machinery labeling

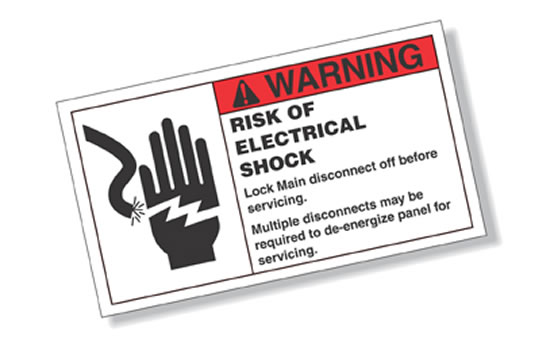

- Safety warning signs

- Product identification and branding

- Warehouse and inventory labeling

- Hazardous material labeling

- Electrical panel labels

- Pipe and valve marking

- Asset tracking labels

- Calibration labels

- Inspection tags

- Serial number labels

- Control panel labels

- Facility signage

- Transportation labels (e.g., on vehicles or shipping containers)

- GHS labeling (for hazardous substances)

Industrial Laminated Stickers Product Features

- Durable and long-lasting

- Resistant to moisture, chemicals, abrasion, and UV rays

- High visibility with vibrant colors and clear printing

- Reliable adhesion to various surfaces

- Available in custom shapes and sizes

- Easy to apply and remove when necessary

- Suitable for indoor and outdoor use

- Can withstand extreme temperatures

- Provides an extra layer of protection for printed information

- Enables customization and branding options

- Cost-effective labeling solution for industrial applications

Types of Industrial Laminated Stickers

Vinyl laminated stickers: These stickers are made from vinyl material and are known for their durability and resistance to the elements. They are often used for outdoor applications that require long-lasting and weather-resistant labels.

Polyester laminated stickers: These stickers are made from polyester material, which provides excellent resistance to tearing, abrasion, and moisture. They are commonly used in environments where durability and high-performance labels are required.

Polypropylene laminated stickers: These stickers are made from polypropylene material, known for its resistance to water, oil, and chemicals. They are ideal for applications that require labels that can withstand exposure to various substances.

Reflective laminated stickers: These stickers are made with reflective material, allowing them to be easily visible in low light or nighttime conditions. They are often used for safety signs, traffic signs, and other applications that require increased visibility.

Reflective laminated stickers: These stickers are made with reflective material, allowing them to be easily visible in low light or nighttime conditions. They are often used for safety signs, traffic signs, and other applications that require increased visibility.

Tamper-evident laminated stickers: These stickers are designed to show clear signs of tampering or removal attempts. They have special adhesive properties or patterns that make it evident if someone tries to peel or remove the sticker.

High-temperature resistant laminated stickers: These stickers are designed to withstand high temperatures without melting or losing their adhesion. They are commonly used in industrial settings where heat resistance is required.

Chemical resistant laminated stickers: These stickers are specially formulated to resist damage or degradation when exposed to chemicals or solvents. They are commonly used in laboratories, chemical processing plants, and other environments where chemicals are present.

Oil and solvent resistant laminated stickers: These stickers are specifically designed to resist oil and solvent exposure without losing their adhesive properties or integrity. They are often used in applications where oil or solvents may come into contact with the label.

Anti-static laminated stickers: These stickers are treated with anti-static properties to prevent the buildup of static electricity. They are commonly used in electronic manufacturing and other environments where static discharge can damage equipment.

Waterproof laminated stickers: These stickers are designed to be fully waterproof, meaning they can be submerged in water without damage. They are commonly used for outdoor applications or in environments with high levels of moisture or humidity.

UV resistant laminated stickers: These stickers have a special coating that protects them from fading or deteriorating when exposed to UV rays from the sun. They are commonly used for outdoor labeling and signage.

UV resistant laminated stickers: These stickers have a special coating that protects them from fading or deteriorating when exposed to UV rays from the sun. They are commonly used for outdoor labeling and signage.

Removable laminated stickers: These stickers are designed to be easily applied and removed without leaving residue or damaging the surface. They are often used in temporary labeling applications or situations where the sticker needs to be repositioned or replaced.

Heavy-duty laminated stickers: These stickers are made with extra-strong adhesive and durable materials to withstand rough handling, extreme weather conditions, or harsh environments.

Static cling laminated stickers: These stickers use static electricity to cling to smooth surfaces without adhesive. They are easy to apply, remove, and reposition, making them ideal for temporary signage, indoor decorations, or retail displays.

Clear laminated stickers: These stickers have a clear background, allowing the underlying surface to show through. They are often used for labeling or branding applications where it is important to maintain visibility of the surface while still providing necessary information.

How Long Do Industrial Laminated Stickers Last?

The lifespan can vary depending on several factors such as the type of sticker, the environment in which it is used, and the level of wear and tear it experiences. In general, industrial laminated stickers are designed to be durable and long-lasting. They are resistant to moisture, chemicals, abrasion, and UV rays, which helps prolong their lifespan.

However, exposure to harsh conditions, frequent handling, or improper application can affect their longevity. On average, industrial laminated stickers can last anywhere from 3 to 5 years or even longer in optimal conditions. Regular inspection and maintenance can help ensure that the stickers remain in good condition and retain their visibility and adhesion over time.

Conclusion

Industrial laminated stickers provide a reliable and versatile labeling solution for a wide range of industrial applications. With their durability, resistance to various elements, and high-performance properties, they can withstand demanding environments and ensure long-lasting visibility. With proper maintenance and installation, they can effectively convey important information, enhance workplace safety, and contribute to efficient operations in industrial settings.

Popular Posts: